Transformer Core Laminations

Precise Electrical Steel Laminations for Transformer Cores

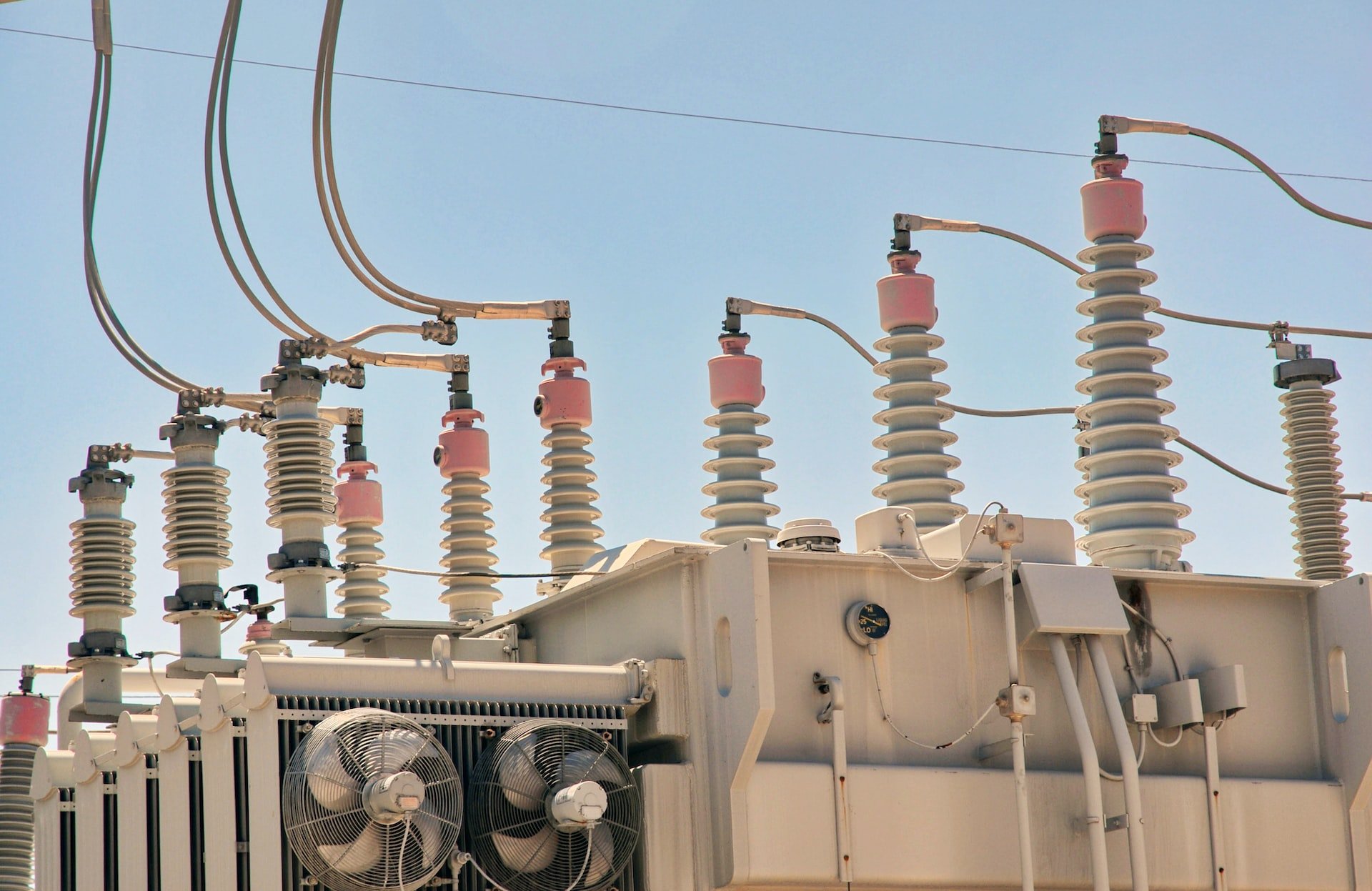

The world is moving toward a more sustainable future. As we transition to a decarbonized and electrified economy, the need for efficient transformer cores is more important than ever. Tempel's premium grain-oriented electrical steel laminations deliver lower core loss and higher performance, making them the perfect choice for a variety of applications, from standard E's and I's laminations to large transformer cores. With our advanced technologies and expertise, we can provide you dimensionally precise stampings to create the higher performing transformer cores that are essential for a sustainable future.

Experience the Innovation and Expertise of Tempel

Material Sourcing Expertise

We are the electrical steel sourcing and metallurgical experts for Non-Grain Oriented (NGO), Grain Oriented (GO), and Cold Rolled Motor Lamination (CRML) steel, with the knowledge and resources to help you select, buy, and source the right material for your application.

Transformer Cores Performance and Efficiency

Boost transformer performance and cut manufacturing costs with precision lamination solutions that reduce core loss and amplify transformer efficiency.

Technical Support

Our design and engineering team is your trusted partner for product development. We'll work with you and your team from ideation to manufacturing, no matter where you are in the world.

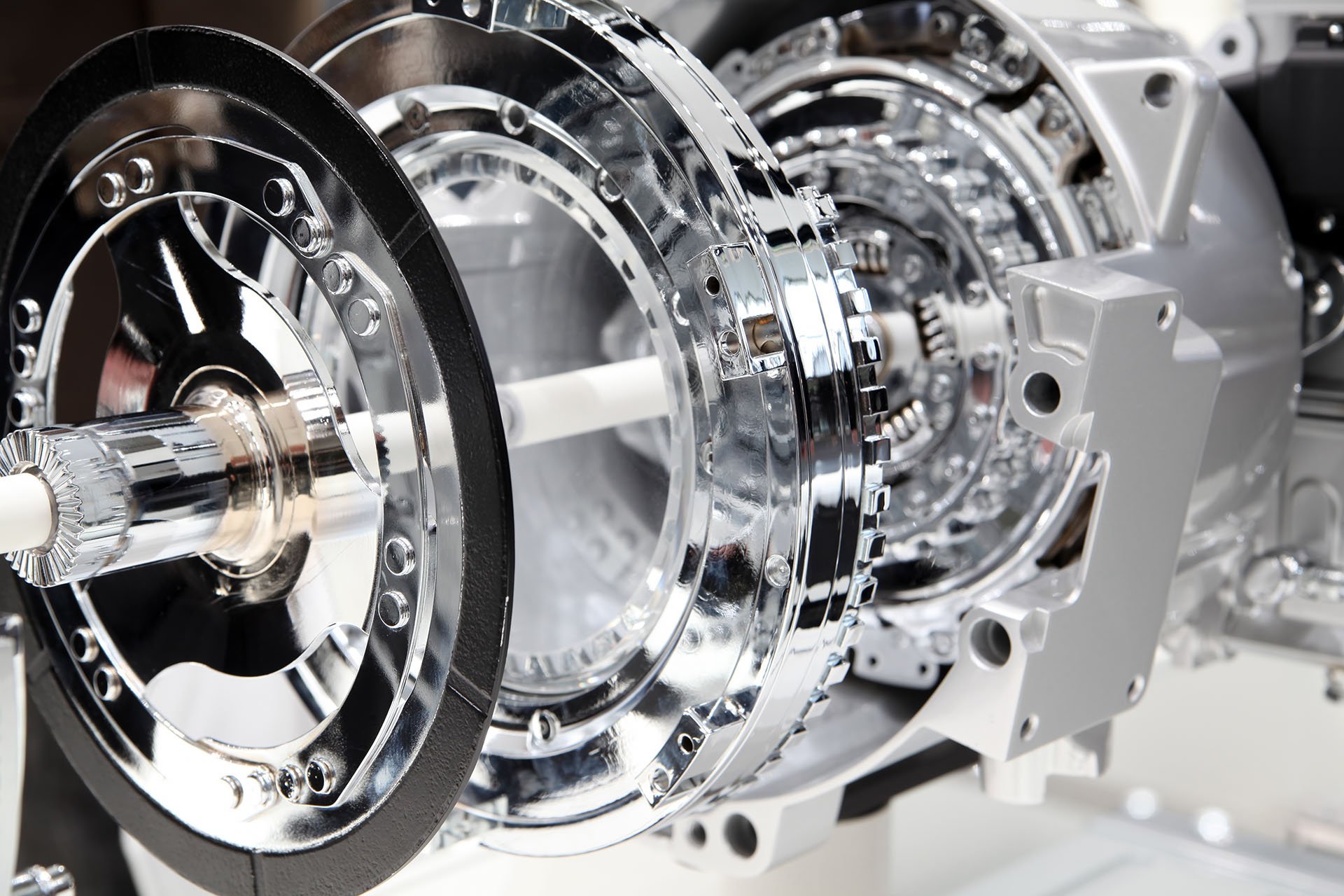

Advanced Stamping and Value-Added Capabilities

We have an exceptional range of highly advanced progressive and large blank and notch stamping capabilities in the world, and we’re uniquely positioned to handle simple to complex production requirements. We also provide critical value-added services including welding, cleating, die-casting, deburring, recoating, and laser cutting.

On-Time, In-Full Delivery

Our high-volume facilities are built for quality and efficiency. We deliver your orders on time, in full, every time.

Transformer Cores and E's and I's Laminations Engineered for Excellence

Achieve higher performance and efficiency in transformer core applications with Tempel’s precise electrical steel lamination stampings. Our range of transformer cores and E's and I's laminations are engineered to meet each customer’s individual needs, ensuring you get the perfect solution for your application.

By Stamping Capabilities

- Miter Core

- E & I

- Step Lap/Miter Core

- DG (Wound) Core

- Cut to Length

E & I

- Instrument and Small Industrial Applications

- Lighting

- Fuel-fired Ignition Transformers

- Small Electronics

- Buck-Boost Transformer

- Impedance Matching

Step Lap/Miter Core

- Larger Power Handling Capability

- Power Transformers

- 3 Phase Pad Mount Utility Transformers

- PDU’s

- Electric Vehicle Charging

- Distribution Transformers (Pole Mount, Pad Mount, Dry and/or Liquid Filled)

- Small and Medium Voltage/Power Transformers for Residential and Light Commercial Use

- VFD Drives / Servo Drives – DIT's

Distributed Gap Wound Core

- Power Transformers

- 3 Phase Pad Mount Utility Transformers

- Power Distribution Units (PDU’s)

- Electric Vehicle Charging

- Distribution Transformers (Pole Mount, Pad Mount, Dry and/or Liquid-Filled)

- Small and Medium Voltage/Power Transformers for Residential and Light Commercial Use

- VFD Drives / Servo Drives – DIT's

Cut to Length

- Dry Type Transformers

- Harmonic Mitigating Transformers

- Rectifying Transformers

U.S. or foreign patents may apply to these products. Please click here for more information.

Electrical Steel Technologies and Engineering for Transformer Laminations

We're more than an electrical steel laminations supplier; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?