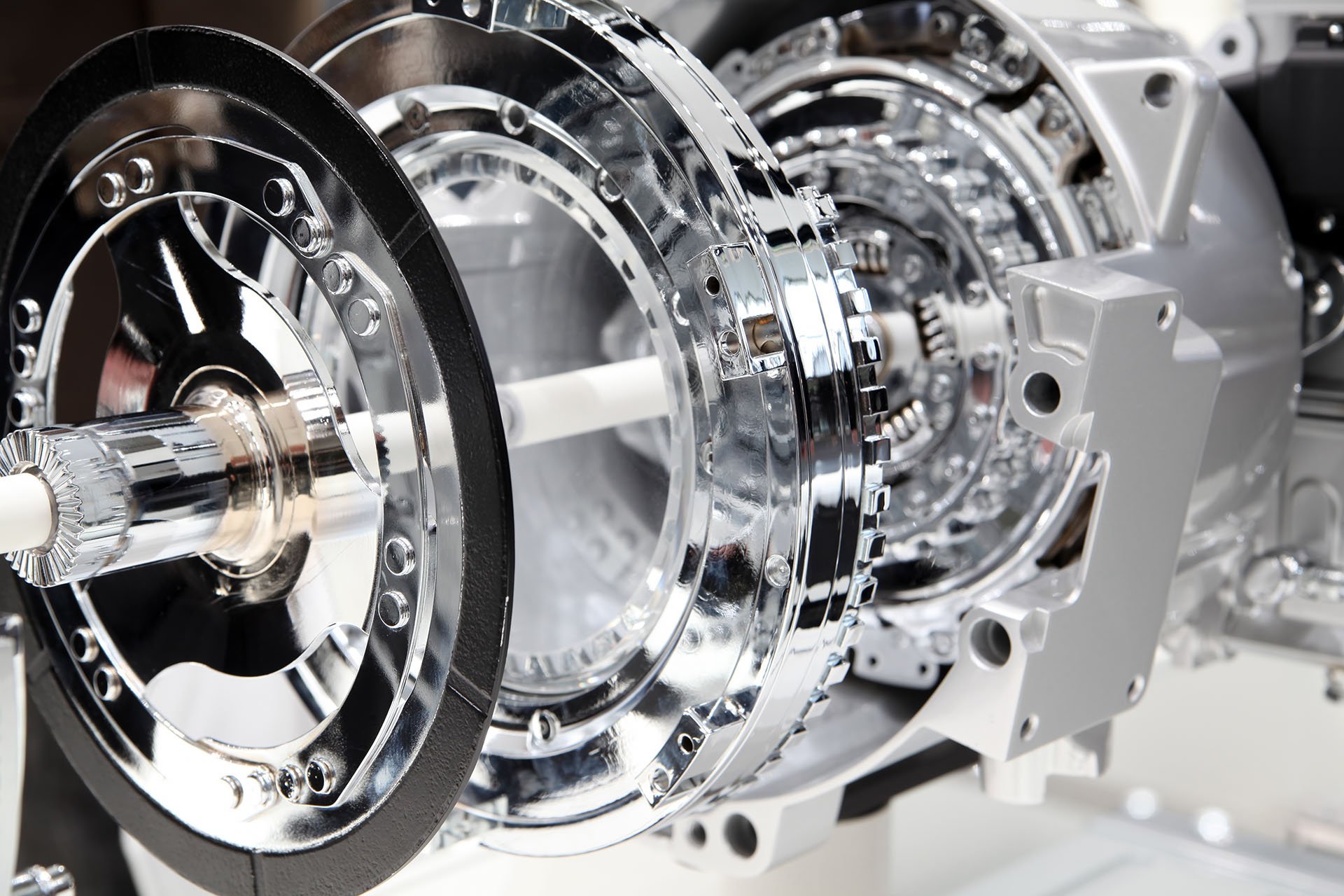

Electrical Steel Annealing

Achieve Enhanced Product Performance with Electrical Steel Annealing

Tempel's annealing capabilities for electrical steel laminations are unmatched in the industry. Our material sourcing expertise, state-of-the-art equipment, and finely tuned annealing process help us optimize magnetic properties to create enhanced product performance and decreased core loss, while reducing overall production costs.

Material Savings

Annealing can improve the magnetic performance of lower-cost materials, making them a viable alternative to more expensive high-alloy grades.

Enhanced Product Quality

Tempel's metal annealing capabilities offer a significant boost in magnetic induction and permeability for enhanced product performance.

Metallurgical Knowledge and Expertise

We are the electrical steel sourcing and metallurgical experts for non-grain oriented (NGO), grain oriented (GO), and cold rolled motor lamination (CRML) steel, with the knowledge and resources to help you select, buy, and source the right material for your application.

U.S. patents or foreign patents may apply to this method for the product. Please visit here for more information.

About Our Process

Tempel's annealing capabilities include a detailed and precise engineering process that involves multiple steps. Please click below to get additional information from our team.

Explore Related Services

We're more than an electrical steel laminations supplier; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?